When choosing a gearmotor, you need to take many different application-related factors into account.

Type of motor, required performance, overall dimensions, cost, efficiency. These are just some of the elements to consider to equip the right gearmotor on your system or machine.

Compact K gearmotors have specific characteristics. They are ideal in those contexts where reduced footprints and costs are essential.

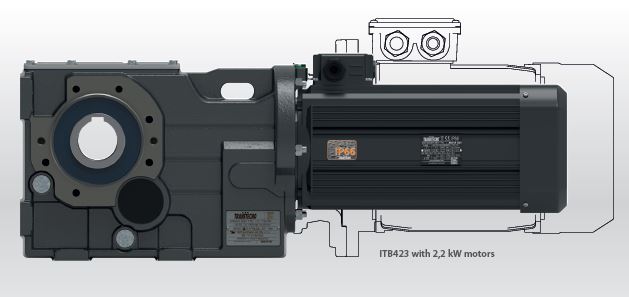

K gearmotors take up less space than the corresponding standard products, allowing space (length) savings. In the K range, we use less components: this is why we can lower the costs.

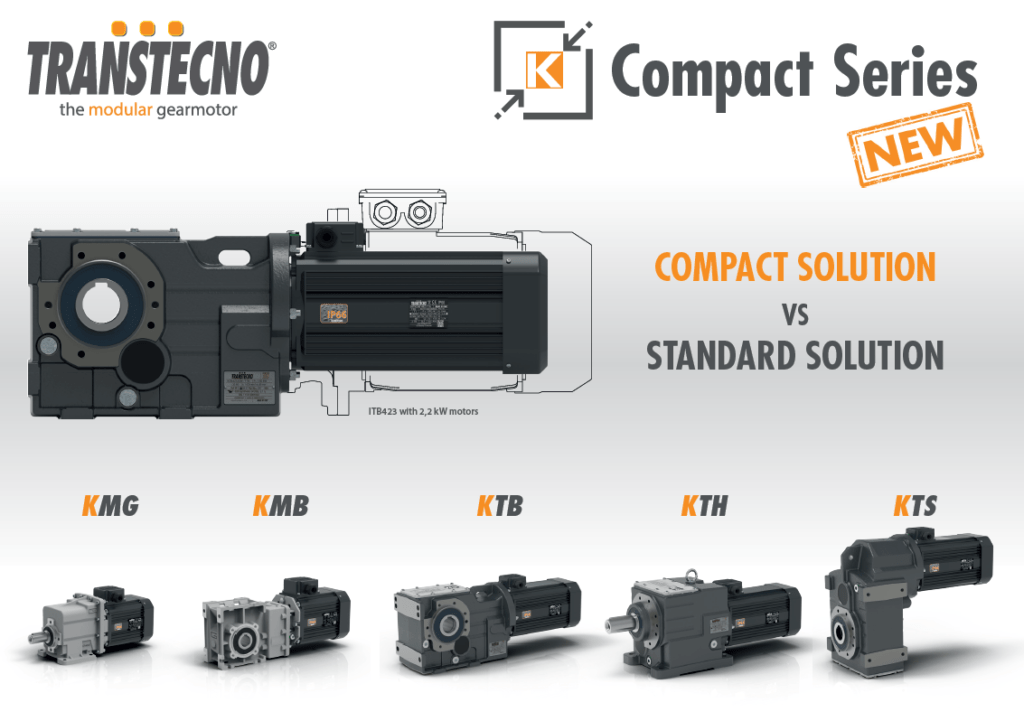

5 Series of compact gearmotors

These are the two main characteristics of the 5 types of compact products we offer, all with an IP66 alternated current motor.

- Gearmotor with aluminium helical in-line gearbox, KMG series.

- Gearmotor with aluminium helical bevel gearbox, KMB series.

- Gearmotors with cast iron helical parallel, helical bevel and helical in-line drives.

Reduced footprint and costs are two additional values. But they are not the only ones.

2 added values, many excellent features

Compact gearmotors do not feature the standard connection between the motor shaft flap and the PAM sleeve: the pinion is fitted directly on the drive shaft.

Thanks to this characteristic, the angular backlash is reduced, compared to traditional couplings with IEC motors; and the gearmotor is particularly suitable for heavy-duty applications with a many starts/stops and direction changes.

The transmission is more reliable and long-lasting. And it has greater efficiency and better performances. Indeed, the shaft, bearing and radial shaft seal are smaller than the PAM. This entails less friction between components. Less friction means a lower operating temperature and higher yield.